Four Ways Grocery Stores Can Take a Lead Role in Solving the Plastics Crisis

May 27, 2021|Heather Putnam

We all know that plastics are a problem – and grocery stores are positioned to help solve it

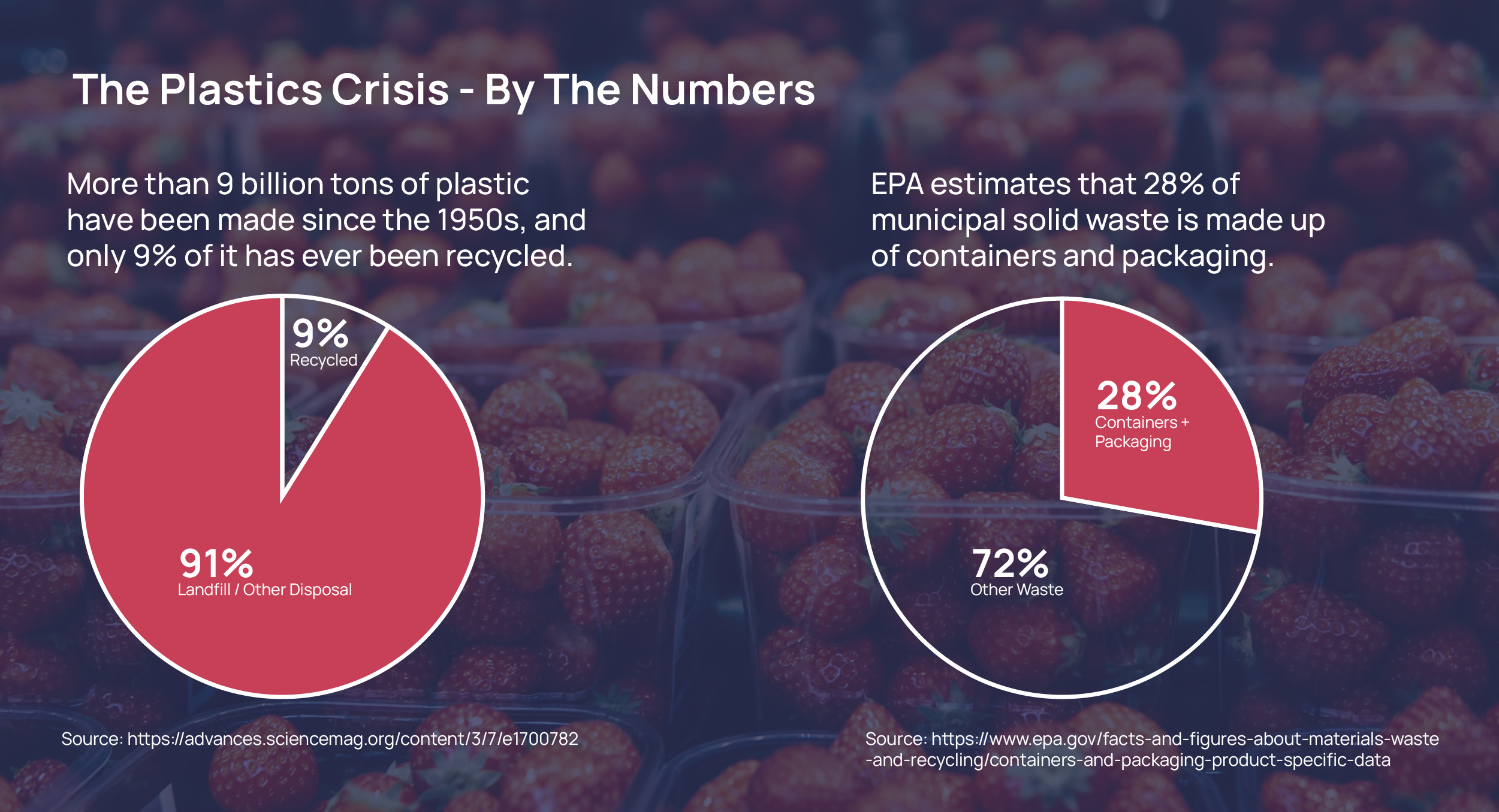

Images of the Great Pacific Garbage Patch and stories of microplastics found in the bodies of sea life fill our newsfeeds, and we know the detrimental effects this plastic pollution has on flora and fauna, air quality, and human health. More than 9 billion tons of plastic have been produced since the 1950s, and only 9% of it has ever been recycled. Much of that plastic has been used in the packaging of food and beverage products, and the EPA estimates that 28% of municipal solid waste is made up of containers and packaging.

Grocery stores are at the center of the plastics crisis. Consumer packaged goods (CPGs) sold in stores are encased in plastic, prepared foods sold in stores are often served in plastic clamshells or wrapped in plastic wrap, and purchased food is still placed in single-use plastic shopping bags throughout most of the country. Cleaning products, medicines, and more are packaged in rigid plastic containers. Some common plastics, like high–density polyethylene (HDPEs) and polyethylene terephthalate (PET), are easily recyclable. HDPEs are used for products like milk. PET is commonly used for jarred products like peanut butter or ketchup. Others, like polystyrene, which is used for disposable cutlery and clamshells, are not easily recyclable. In fact, most plastics used are not recyclable within our current recycling infrastructure. Mixed-materials containers, including chips cans that are made of fused cardboard and foil lining with a metal base and plastic lid, are impossible to recycle.

Food retailers are in a challenging position and face intensifying pressure to act to reduce plastic waste. Regulations to require recyclable plastics, ban single-use plastics, and improve recycling systems are increasing, and civil society is increasingly demanding action – in December, 2020, a coalition of 550 community and conservation organizations urged President Biden to solve the crisis through executive actions such as restricting plastic production, and a Change.org petition was launched to demand that Trader Joe’s and Whole Foods Markets reduce plastic waste in their stores.

But the food retail industry, as the nexus of our food system, has an opportunity to lead by reducing its dependence on plastic packaging, promoting more effective recycling practices in its operations and among customers, and partnering with others to improve the country’s recycling infrastructure. Given the number of customers stores serve each day, they could be very influential in discouraging single-use plastics, but they can also play a role in reducing the industry’s dependence on plastic altogether. The challenge for retailers lies in the monetary equation. The revenue gained from recycling plastic waste is negligible when compared to the money saved by avoiding plastic disposal all together. Furthermore, the cost of non-plastic alternatives is typically higher than virgin plastic containers, and the cost of virgin plastic containers is also typically lower than containers made of recycled resins. These challenges must be met through cross-sector collaboration to transition to safer, less impactful solutions.

Four Things Food Retailers Can Do to Address the Plastics Crisis

1. Reduce Single–Use Plastics and Packaging in Operations

Retailers can work to identify opportunities to reduce single-use plastics and packaging in their own operations and find alternatives to plastics. Retailers offering prepackaged prepared foods like salads, cut fruit, and ready-made meals can find alternatives to plastic clamshells and tubs. Bioplastics like starch-based plastic or PLA containers, utensils, and straws are problematic because they are only compostable in industrial composting plants, and used PLA containers are not likely to make it to industrial composting facilities once they are discarded, either at the store or at home. Only a small fraction of the 4000 composting facilities in the U.S. can accept bioplastics. An alternative is to convert prepared-food packaging to less impactful non-plastic materials that are reusable or recyclable, like paperboard to-go containers. The key to all of these alternatives is ensuring adequate labelling and education for consumers to know which containers go into the recycling bin, which into municipal composting bins (if available), and which can be reused. Finally, an even more radical idea was piloted in 2019 in Quebec by the grocery chain Metro, which began allowing customers to fill their own reusable containers for ready-made meals, meat, seafood, and bakery items. This approach, if coupled with messaging to customers about how to safely fill their own containers, has the potential to dramatically reduce the use of packaging and its associated cost.

2. Work With Suppliers to Reduce Plastic CPG Packaging or Convert to Easier-to-Recover Alternatives

Most plastic sold out of grocery stores exists in the form of CPG packaging. Retailers can partner with CPG companies to support their conversion to sustainable packaging. A major hurdle to the recycling or reuse of CPG packaging is that it often contains mixed materials that are not easily separated or recoverable, as in the case of tetrahedron cartons or juice pouches, making reuse or recycling extremely difficult.

But there is hope. The 25 largest CPG companies have all made sustainable packaging commitments ranging from sourcing (as in Mars’s goal of 25% reduction in virgin plastic by 2025) to waste reduction goals (like Nestlé’s goal of 100% recyclable or reusable packaging by 2025). Others, like Unilever, PepsiCo, and Coca-Cola are also pursuing plastic-free packaging solutions like paperboard, supporting their goals of reducing sourcing of virgin plastics. An example of a partnership between food retailers, CPG companies, and innovators takes single-use packaging out of the picture entirely. Both Kroger and Walgreens have partnered with Loop to offer products like Häagen–Dazs ice cream, Nature’s Path granola, and more in containers that can be returned and reused.

3. Create Effective Recycling Systems and Promote Good Recycling Practices to Customers

Improving recycling rates in stores involves not only educating employees, but also overcoming infrastructure challenges. One challenge that grocers face is the recycling of “behind-the-counter” plastic containers: rigid plastic containers made of HDPE (#2) or polypropylene (PP, #5) resins. These food-grade containers are typically used in the bakery, deli, seafood, and pharmacy departments, and are highly valuable in the recycling marketplace. However, most grocers don’t have the organizational or physical infrastructure to compile high enough volumes of them to sell to recyclers. “It has to be a management decision,” says Kate Eagles, Program Director at the Association of Plastics Recyclers (APR), “Effective recycling of these requires understanding of volumes, determining a market, and working through in-store logistics and consolidation sites.” Grocers must find ways to clean, compile, sort, and get the materials as close to bailing as possible to get the most value from them.

Educating consumers about effective recycling practices is also critical. When plastics packaging must be used, a hurdle to reducing plastics waste is consumers knowing how and where to recycle it. Retailers can create or support consumer education programs to help customers know what types of packaging can be recycled and where to recycle it. The most common retail solution is plastic grocery bag and film recycling containers positioned at the front of the store, but these are not available at every store, and do not address helping consumers recycle other forms of plastic packaging and containers obtained at the grocery store, namely rigid plastic containers.

An overarching systemic challenge is that existing recycling infrastructure in the U.S. is inadequate to recycle most plastics, and has outdated recycling technology. However, policy makers, major CPG companies, and industry associations recognize that systemic changes are needed to increase recycling rates, including technology innovations, updates to existing infrastructure, and new programs.

4. Partner With Others to Change the System

Various partnerships, coalitions, and nonprofit organizations are dedicated to improving recycling infrastructure, reducing plastic usage, or promoting the plastic circular economy.

Target, Walmart, and the FMI are part of the US Plastics Pact, which brings together businesses, government, nonprofits, researchers, and other stakeholders to “ensure that plastics never become waste by eliminating the plastics we don’t need, innovating to ensure that the plastics we do need are reusable, recyclable, or compostable, and circulating all the plastic items we use to keep them in the economy and out of the environment.” Its approach recognizes that retailers or other individual actors cannot achieve zero plastic waste on their own, but must work together to change systems that produce, use, recover, and process plastics.

The Association of Plastic Recyclers (APR) Recycle Grocery Rigid Plastics Program offers tools and resources, including a complete “how-to” guide, to help grocers build successful rigid plastics recycling programs, and a bailing economic calculator to determine market values for rigid plastics.

The Recycling Partnership is working with industry actors to improve available data on film and flexible–packaging plastic recycling as a commodity and its recycling rates.

The Plastics Industry Association (PLASTICS) is working with regulators to legislate improvements to U.S. recycling infrastructure.

This article was published in partnership with Presidio Graduate School.